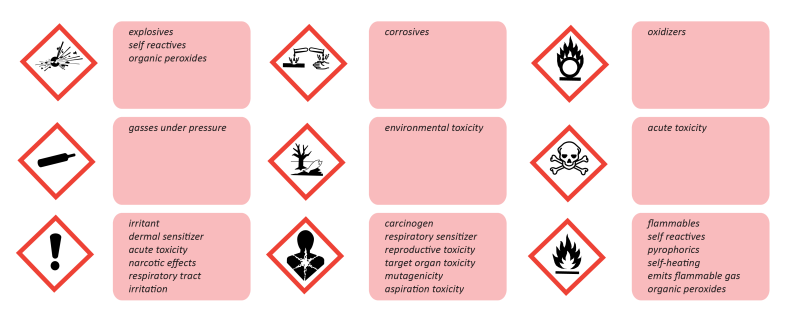

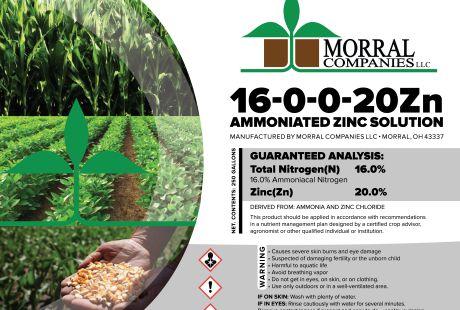

Under the new GHS compliance mandates, chemical drums need to be properly marked with hazard warnings before they can be legally distributed. “BS5609” is an international label standard that determines whether a specific label can be used on these chemical containers as they are being shipped overseas. As a significant portion of international trade is carried out by water, any large chemical company or company that produces products with chemical components need to use labels that will survive oceanic conditions. To become BS5609 certified, the material and the label adhesive must pass International Maritime Dangerous Goods (IMDG) certification tests of permanence and durability under conditions of marine exposure, such as temperature fluctuations, submersion, cuts and scrapes, and exposure to seawater, sunlight, and chemicals. Simply put, BS5609 labels must be able to stick to its drum even if the barrel falls overboard, so that if the drum is recovered or washes up on a coastline, the information can still be read. In this way, BS5609 labels guarantee the safety of chemical and shipping crews as well as the safety of the general public.

If your company works with hazardous materials, you know that your business is subject to strict safety regulations. One of the most important safety requirements is maintaining proper labels that identify each chemical and define the dangers they could pose to employees or the environment. With GHS labels from Paragon, you can ensure your workers will be protected.